Friday, August 05, 2005

Shuttle Tile Repair Technology Described in AW&ST

After inspecting the thermal tiles, removing some protruding gap filler material on its belly, and receiving instructions to leave a damaged thermal blanket alone, the space shuttle Discovery’s crew is ready to return to Earth. In honor of this shuttle flight’s first ever in-orbit repair of a spacecraft’s thermal protection system (tps) I am posting a review of Aviation Week and Space Technology’s (AW&ST) pair of articles by Bruce A. Smith from their August 18th and August 25th issues on the development of the shuttle’s in-orbit repair kit and procedures by Martin Marietta. No, this isn’t a case of laphamization on AW&ST’s part. Neither do I have a time machine. These articles were published a quarter century ago this month, in August 1980. Occasionally when NASA officials or aerospace experts talk about in-orbit tps repair they will mention that early in the shuttle program they attempted to develop tps repair technology but the effort ran into problems and was abandoned. It is this early attempt to develop tps repair capabilities for the space shuttle that these two articles describe.

The first article from Aug. 18, 1980 titled "Backpack Modified for Tile Repair Use" begins:

Denver- Operational mode of the maneuvering backpack for space shuttle astronauts has been modified to reflect the more important role the system may play during early shuttle flights if it is necessary to inspect and repair the orbiter’s thermal protection system tiles in space.

The 330lb. backpack initially was developed as a means of increasing astronaut mobility during operational shuttle missions as crewmembers performed extravehicular tasks such as servicing spacecraft, transferring payloads from nearby satellites or building large space structures.

A new dimension was added to the manned maneuvering unit (MMU) program, however, when it was determined that some thermal tiles might be damaged during early shuttle launches and require repair prior to reentry. As a result, Martin Marietta last year was requested to expedite development of the backpacks so it could be available for initial shuttle missions if necessary.

The article explains that a tether would connect the astronaut to the shuttle, in case the MMU system malfunctioned. The author describes being allowed to test fly an MMU simulator at length and mentions the deliberate similarity between the shuttle’s and MMU’s controls.

The second article from Aug. 25, 1980 titled: "In-Orbit Tile Repair Plans Developed" begins:

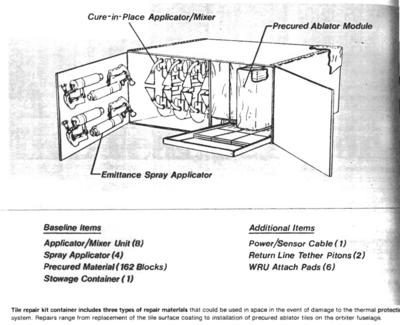

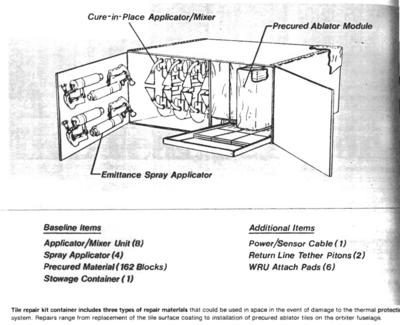

Denver- Three types of tile repair materials and a small work station are being developed to provide space shuttle astronauts with the capability of repairing possible damage to the orbiter’s thermal protection system ranging from chips or cracks in the black tile coating to the loss of sections of tiles.

The shuttle tile repair kit and the astronaut work restraint unit are part of an inspection and repair system that is being readied on a schedule to support early shuttle flights, although there currently are no plans to include the equipment on the first shuttle mission.

Not to worry, though, I’m sure they’ll add that equipment eventually. The article describes the way a tile inspection would be conducted:

A tile inspection mission would take about one hour to conduct, beginning with the nose of the orbiter and extending back to the elevons and body flap at the aft end of the vehicle. The inspection would cover all of the black high-temperature tiles on the bottom of the shuttle and would be scheduled to occur during a daylight period, although astronauts would be equipped with lights on their helmets to aid in the inspection process if necessary. The crew-member then would return to the cargo bay either to return to the crew compartment or to refuel the backpack and pick up required materials for repairs.

Stickypad tether holders and a short boom would keep the emergency tether from becoming tangled during the inspection process. The repair equipment is described as consisting of three main items:

• Pressurized sprayers-called emittance spray applicators-to replace the thin black coating over the high-temperature tiles, which is necessary to retain their thermal characteristics. The four spray guns, which will be furnished by Johnson Space Center, will include a back-scatter spray shield to keep any possible back-spray off the astronaut’s visor.

• Eight cure-in-place applicator/mixer devices to provide semi solid material, which may be used to repair tile damage over small areas that is deeper than the thin layer of black coating. The unit mixes and dispenses a resin and catalyst that cure in place on the tile surface to form a hard ablative shield during reentry. The material will be in a workable consistency for about one hour and cure in 18 hours. Program officials said that a depression or bump up to 0.25in. below or above the normal shuttle surface would not affect the aerodynamics of the shuttle.

• Pre-cured blocks of ablative tile to be used if larger areas of the shuttle’s protective tile covering were damaged or lost. The blocks, roughly six inches square, will be scored vertically, horizontally, and at angles so they can be shaped to more closely fit the desired space. The cure-in-place material would be used to bond the pre-cured blocks in place and to fill the gaps between the tiles.

Two images with the article that depict the repair kit are attached below.

Now, twenty-five years later, NASA describes the new tile repair system they have developed as consisting of three main technologies:

First is an emmitance wash that is sprayed on with a pressurized sprayer (Hey guys, don’t forget about that back-scatter shield).

Second is a cure-in-place “goo” that forms a hard ablative shield. Some pictures seem to show that the pre-cured ablative blocks described by Smith’s article are also considered part of this technology. If so, it is not clear why they have combined these two items into one list entry in their presentation, although perhaps NASA believes that briefing lists longer than three items become too confusing.

Third is flexible insulation that is stuffed into large holes and a patch that is bolted onto the orbiter’s surface to hold it in. Unlike the rest of the tps repair system, this technology doesn’t seem to have a predecessor in the original tps repair kit Smith describes.

Tile inspection technology has also changed to make use of the Canada arm. The similarity of the rest of the system to the original tps repair kit makes me curious about the circumstances under which the original tps repair system development was abandoned. Do we have some new 21st century technology that is essential to making it work which just wasn’t available then? Or did early luck with re-entering the shuttle on damaged tiles convince NASA that tps inspection and repair was unnecessary, until the Columbia accident forced them to reconsider that decision? Were they right then to not risk in-orbit repairs, and now they are developing it anyway just to look like they are Doing Something? If there are any rocket scientists who could give me the history of that decision, I’d like to know.

Update: Welcome Transterrestrials. I encourage you to look around the blog and see if there is anything else you like. Aerospace aficionados may particularly find the post The Japanese/French Son-of-Concorde vs. the Quiet Small Supersonic Transport interesting.

Update 2: Dwayne A. Day has an informative comment on this issue at Transterrestrial Musings. A portion of that comment which explains what happened to the original shuttle tile repair kit is copied below:

I discussed this at length with Sally Ride (a CAIB Board member) who suggested that I discuss it with STS-1 pilot Robert Crippen. Ride explained that it was the STS-1 crew that ultimately put the brakes on the tile repair effort. As she remembered, there were several reasons for this. One of these reasons was that they thought it was totally unreasonable to expect a two-man crew to conduct an EVA, particularly underneath the vehicle. This would have been using the untested MMU as well. I believe that another reason was that they already had too much to do for their test flight and did not want more things added to their training schedule.

So TPS repair got dropped early, with STS-1, and apparently was considered impractical for those early two-man test flights.

I did ask why it was never picked up again after the shuttle was declared "operational," but I cannot remember Ride's answer. I think she may have said that the astronauts thought tile repair was impractical. Plus, by that time they had an idea of the fragility of the TPS system and believed that damage (some damage, anyway) was survivable.

Thanks for the infromation, Dr. Day.

The first article from Aug. 18, 1980 titled "Backpack Modified for Tile Repair Use" begins:

Denver- Operational mode of the maneuvering backpack for space shuttle astronauts has been modified to reflect the more important role the system may play during early shuttle flights if it is necessary to inspect and repair the orbiter’s thermal protection system tiles in space.

The 330lb. backpack initially was developed as a means of increasing astronaut mobility during operational shuttle missions as crewmembers performed extravehicular tasks such as servicing spacecraft, transferring payloads from nearby satellites or building large space structures.

A new dimension was added to the manned maneuvering unit (MMU) program, however, when it was determined that some thermal tiles might be damaged during early shuttle launches and require repair prior to reentry. As a result, Martin Marietta last year was requested to expedite development of the backpacks so it could be available for initial shuttle missions if necessary.

The article explains that a tether would connect the astronaut to the shuttle, in case the MMU system malfunctioned. The author describes being allowed to test fly an MMU simulator at length and mentions the deliberate similarity between the shuttle’s and MMU’s controls.

The second article from Aug. 25, 1980 titled: "In-Orbit Tile Repair Plans Developed" begins:

Denver- Three types of tile repair materials and a small work station are being developed to provide space shuttle astronauts with the capability of repairing possible damage to the orbiter’s thermal protection system ranging from chips or cracks in the black tile coating to the loss of sections of tiles.

The shuttle tile repair kit and the astronaut work restraint unit are part of an inspection and repair system that is being readied on a schedule to support early shuttle flights, although there currently are no plans to include the equipment on the first shuttle mission.

Not to worry, though, I’m sure they’ll add that equipment eventually. The article describes the way a tile inspection would be conducted:

A tile inspection mission would take about one hour to conduct, beginning with the nose of the orbiter and extending back to the elevons and body flap at the aft end of the vehicle. The inspection would cover all of the black high-temperature tiles on the bottom of the shuttle and would be scheduled to occur during a daylight period, although astronauts would be equipped with lights on their helmets to aid in the inspection process if necessary. The crew-member then would return to the cargo bay either to return to the crew compartment or to refuel the backpack and pick up required materials for repairs.

Stickypad tether holders and a short boom would keep the emergency tether from becoming tangled during the inspection process. The repair equipment is described as consisting of three main items:

• Pressurized sprayers-called emittance spray applicators-to replace the thin black coating over the high-temperature tiles, which is necessary to retain their thermal characteristics. The four spray guns, which will be furnished by Johnson Space Center, will include a back-scatter spray shield to keep any possible back-spray off the astronaut’s visor.

• Eight cure-in-place applicator/mixer devices to provide semi solid material, which may be used to repair tile damage over small areas that is deeper than the thin layer of black coating. The unit mixes and dispenses a resin and catalyst that cure in place on the tile surface to form a hard ablative shield during reentry. The material will be in a workable consistency for about one hour and cure in 18 hours. Program officials said that a depression or bump up to 0.25in. below or above the normal shuttle surface would not affect the aerodynamics of the shuttle.

• Pre-cured blocks of ablative tile to be used if larger areas of the shuttle’s protective tile covering were damaged or lost. The blocks, roughly six inches square, will be scored vertically, horizontally, and at angles so they can be shaped to more closely fit the desired space. The cure-in-place material would be used to bond the pre-cured blocks in place and to fill the gaps between the tiles.

Two images with the article that depict the repair kit are attached below.

Now, twenty-five years later, NASA describes the new tile repair system they have developed as consisting of three main technologies:

First is an emmitance wash that is sprayed on with a pressurized sprayer (Hey guys, don’t forget about that back-scatter shield).

Second is a cure-in-place “goo” that forms a hard ablative shield. Some pictures seem to show that the pre-cured ablative blocks described by Smith’s article are also considered part of this technology. If so, it is not clear why they have combined these two items into one list entry in their presentation, although perhaps NASA believes that briefing lists longer than three items become too confusing.

Third is flexible insulation that is stuffed into large holes and a patch that is bolted onto the orbiter’s surface to hold it in. Unlike the rest of the tps repair system, this technology doesn’t seem to have a predecessor in the original tps repair kit Smith describes.

Tile inspection technology has also changed to make use of the Canada arm. The similarity of the rest of the system to the original tps repair kit makes me curious about the circumstances under which the original tps repair system development was abandoned. Do we have some new 21st century technology that is essential to making it work which just wasn’t available then? Or did early luck with re-entering the shuttle on damaged tiles convince NASA that tps inspection and repair was unnecessary, until the Columbia accident forced them to reconsider that decision? Were they right then to not risk in-orbit repairs, and now they are developing it anyway just to look like they are Doing Something? If there are any rocket scientists who could give me the history of that decision, I’d like to know.

Update: Welcome Transterrestrials. I encourage you to look around the blog and see if there is anything else you like. Aerospace aficionados may particularly find the post The Japanese/French Son-of-Concorde vs. the Quiet Small Supersonic Transport interesting.

Update 2: Dwayne A. Day has an informative comment on this issue at Transterrestrial Musings. A portion of that comment which explains what happened to the original shuttle tile repair kit is copied below:

I discussed this at length with Sally Ride (a CAIB Board member) who suggested that I discuss it with STS-1 pilot Robert Crippen. Ride explained that it was the STS-1 crew that ultimately put the brakes on the tile repair effort. As she remembered, there were several reasons for this. One of these reasons was that they thought it was totally unreasonable to expect a two-man crew to conduct an EVA, particularly underneath the vehicle. This would have been using the untested MMU as well. I believe that another reason was that they already had too much to do for their test flight and did not want more things added to their training schedule.

So TPS repair got dropped early, with STS-1, and apparently was considered impractical for those early two-man test flights.

I did ask why it was never picked up again after the shuttle was declared "operational," but I cannot remember Ride's answer. I think she may have said that the astronauts thought tile repair was impractical. Plus, by that time they had an idea of the fragility of the TPS system and believed that damage (some damage, anyway) was survivable.

Thanks for the infromation, Dr. Day.

Comments:

<< Home

From a comment I posted over at Rand's place: The person to ask is Bonnie Dunbar. She was a TPS engineer before becoming an astronaut. NASA developed a repair material and some of the tools. One major problem was that the repair material had a very short working time after it was mixed if not kept heated - it was an epoxy of sorts. The applicator tools were power hungry, bulky, and there was concern about stabilizing the crew doing the repair without damaging the tiles further. The whole problem ballooned into needing more and more equipment.

The new repair goo has better characteristics and EVA is simpler since the station arm can get the crew to the underside of the shuttle.

Post a Comment

The new repair goo has better characteristics and EVA is simpler since the station arm can get the crew to the underside of the shuttle.

<< Home